Spinning Wheel Design (Idea)

Was just pondering spinning wheels since my housemate’s boyfriend built her an electric one that works pretty good. However, it IS electric which means it is still post-industrial revolution and requires a 110V 60Hz power hookup.

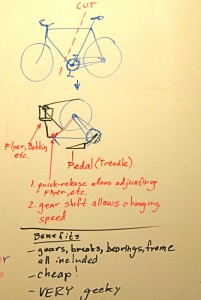

What if you cut a bicycle frame (see photo) such that the sprocket, gears, rear wheel, and seat were all still intact. You could attach a treadle to where the crank-shafts once were and make sure the rear hub couldn’t rotate freely. You could run the gear changers (if it’s a multi-speec bike) up near the seat post allowing the spinner to change speeds. With the wheel no longer on free-rotate, the break would be unecessary.

The flyer, bobbin, and other-parts-I-don’t-know-the-names-of could be attached to the seat post and the quick-release used to quickly adjust distance from the wheel or to remove that section for necessary repairs, loading, etc (again I don’t know enough about spinning wheels to judge what is necessary there).

One thing the boyfriend mentioned was the difficulty of keeping costs down… I’m sure you can find part of a bike to use for around $20 and it comes with so much built in. If anyone ever implements (or has already implemented) a design like this, please let me know. 🙂

Cool!

darrell,

great idea!

i’m not a spinner but i believe it requires at least one hand free to moderate the flow of fiber. so, i would take this design in two directions.

1. chances are in the third world a stationary bicycle is already used extensively to power micro-businesses that spin fiber into thread or yarn. try googling for images (lacking broadband, i suggest someone else search the net). this covers the small scale semi-automated production pattern.

2. for the solo spinner, a foot treadle leaving both hands free to moderate the flow of fiber is probably optimal for a human powered spinning operation.

see also

http://en.wikipedia.org/wiki/Spinning_(textiles)#Contemporary_hand_spinning

love, dad

I had an idea for this just a little while ago!

I AM a spinner so I will tell you a few basic things- When someone starts spinning yarn, it is called a singles-never a 1-ply yarn! If the spinner decides to ply it, it needs to be spun in the opposite direction of the singles that make it up. One big problem is that a derailleur will only turn the wheel in one direction. Now it IS possible to have a wheel simply for spinning singles or plying, it’s just slightly less economical. My boyfriend has a Trek mountain bike fitted with a gear shifting system that is just a lever, and tht is what gave me the idea, being able to “increase the throttle” with just a lever. If I ever come across the parts for cheap, I certainly would build it!! 😀